Dear Customers!

We would like to notify you that our shop will be closed from 15.12.2023 to 03.01.2024.

During these days, we will be unable to respond to telephone calls or emails.

Closing date: 2023.12.15 12:00.

Opening date: 2024.01.04 8:00.

During the holiday, our webshop is going to be fully functional, you will be able to place orders, which will be shipped in the following rules:

Orders placed during the holidays will be processed based on the order of arrival on the 4th of January, 2023. Depending on the number of orders, the usual delivery time may increase. We will try everything to deliver all orders as soon as possible.

We would like to wish everyone merry christmas and a succesful new year!

Viscosity and Viscosity Index of Compressor Oils

Compressor oil plays a key role in the appropriate and long term functioning of compressors. As it is responsible for making a proper film layer between the moving parts (e.g. piston, cylinder), and for cooling the components, therefore it is very important that what kind of combination ability the specific compressor oil has with the used refrigerant, and what kind of viscosity index belongs to the given oil.

Viscosity of Compressor Oils

One of the important criteria in case of compressor oil is its viscosity. The term viscosity describes the given liquid’s resistance to flow, so an oil with bigger viscosity flows less, and an oil with lower viscosity is thin fluid. The kinematic viscosity describes the oil’s flowing time on a given temperature, its unit in the SI-system is mm2/s, or the commonly used centiStoke (cSt). Thus 1 cSt ≈ 1 mm2/s. In the base of this kinematic viscosity the ISO 3448:1992 standard defines a viscosity group system which determines the minimal and maximal kinetic viscosity point of a given oil on 40° Celsius. The average value derived from this two points indicates the name of the given group. Accordingly, e.g. an oil which has a minimal viscosity of 28 mm2/s, and a maximal viscosity of 35.2 mm2/s, takes place in the group ISO VG 32. (The VG means Viscosity Group). Though viscosity is affected by several factors (e.g. the kinetic speed of the components, and the quality of machining), essentially it needs to be striving after picking the lower but still satisfying viscosity classification.

| ISO 3448 Viscosity Group (40°C) | Minimal Kinetic Viscosity (mm2/s) | Maximal Kinetic Viscosity (mm2/s) | Kinetic Viscosity Midpoint (mm2/s) |

| ISO VG 2 | 1.98 | 2.42 | 2.2 |

| ISO VG 3 | 2.88 | 3.52 | 3.2 |

| ISO VG 5 | 4.14 | 5.06 | 4.6 |

| ISO VG 7 | 6.12 | 7.48 | 6.8 |

| ISO VG 10 | 9 | 11 | 10 |

| ISO VG 15 | 13.5 | 16.5 | 15 |

| ISO VG 22 | 19.8 | 24.2 | 22 |

| ISO VG 32 | 28.8 | 35.2 | 32 |

| ISO VG 46 | 41.4 | 50.6 | 46 |

| ISO VG 68 | 51.2 | 74.8 | 68 |

| ISO VG 100 | 90 | 110 | 100 |

| ISO VG 150 | 135 | 165 | 150 |

| ISO VG 220 | 198 | 242 | 220 |

| ISO VG 320 | 288 | 352 | 320 |

| ISO VG 460 | 414 | 506 | 460 |

| ISO VG 680 | 612 | 748 | 680 |

| ISO VG 1000 | 900 | 1100 | 1000 |

| ISO VG1500 | 1350 | 1650 | 1500 |

Determining the Viscosity Index of Compressor Oils

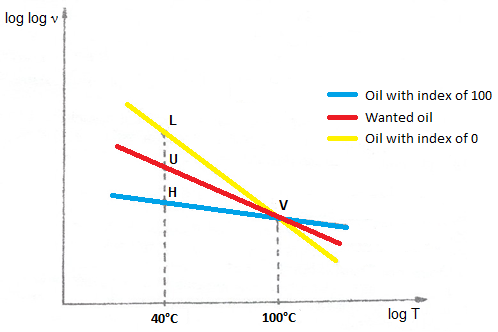

The other critical characteristic of compressor oils which is important in case of cooling the components too is the alteration of viscosity due to temperature changing. The alteration of viscosity is described by the viscosity index (VI) which shows that how the viscosity of the given oil changes due to temperature changing, so the index number indicates the alteration of viscosity, not the viscosity itself. If the temperature of the oil rises, its viscosity will decrease; and if the temperature of the oil is down, its viscosity will get larger. The viscosity of the oils (known as ’paraffinic oils’) that has the best viscosity index (= 100) alters less, while in case of the oils (known as ’naphthenic oils’) which has the worst viscosity index (= 0) the viscosity changes in a large measure. So in case of the paraffinic and of naphthenic oils, too, there is a viscosity index based sequence, by which the kinematic viscosity of the specific oil is given. To determine the viscosity index of a specific oil, it needs to be picking one from those paraffinic and one from those naphthenic base oils, which have the same value of viscosity index at 100°C as the wanted oil has at 100°C. The following table summarizes the kinematic viscosity of the base oils at 100°C, in addition it contains a value (L) for the base oils which have the viscosity index of 0 at 40°C, and another value (H) for the base oils which have the viscosity index of 100 at 40°C.

| Kinetic Viscosity (ν) (100°C. mm2/s) | L | H |

| 2.00 | 7.994 | 6.394 |

| 2.10 | 8.640 | 6.894 |

| 2.20 | 9.309 | 7.410 |

| 2.30 | 10.00 | 7.944 |

| 2.40 | 10.71 | 8.496 |

| 2.50 | 11.45 | 9.063 |

| 2.60 | 12.21 | 9.647 |

| 2.70 | 13.00 | 10.25 |

| 2.80 | 13.80 | 10.87 |

| 2.90 | 14.63 | 11.50 |

| 3.00 | 15.49 | 12.15 |

| 3.10 | 16.36 | 12.82 |

| 3.20 | 17.26 | 13.51 |

| 3.30 | 18.18 | 14.21 |

| 3.40 | 19.12 | 14.93 |

| 3.50 | 20.09 | 15.66 |

| 3.60 | 21.08 | 16.42 |

| 3.70 | 22.09 | 17.19 |

| 3.80 | 23.13 | 17.97 |

| 3.90 | 24.19 | 18.77 |

| 4.00 | 25.32 | 19.56 |

| 4.10 | 26.50 | 20.37 |

| 4.20 | 27.75 | 21.21 |

| 4.30 | 29.07 | 22.05 |

| 4.40 | 30.48 | 22.92 |

| 4.50 | 31.96 | 23.81 |

| 4.60 | 33.52 | 24.71 |

| 4.70 | 35.13 | 25.63 |

| 4.80 | 36.79 | 26.57 |

| 4.90 | 38.50 | 27.53 |

| 5.00 | 40.23 | 28.49 |

| 5.10 | 41.99 | 29.46 |

| 5.20 | 43.76 | 30.43 |

| 5.30 | 45.53 | 31.40 |

| 5.40 | 47.31 | 32.37 |

| 5.50 | 49.09 | 33.34 |

| 5.60 | 50.87 | 34.32 |

| 5.70 | 52.64 | 35.29 |

| 5.80 | 54.42 | 36.26 |

| 5.90 | 56.20 | 37.23 |

| 6.00 | 57.97 | 38.19 |

| 6.10 | 59.74 | 39.17 |

| 6.20 | 61.52 | 40.15 |

| 6.30 | 63.32 | 41.13 |

| 6.40 | 65.18 | 42.14 |

| 6.50 | 67.12 | 43.18 |

| 6.60 | 69.16 | 44.24 |

| 6.70 | 71.29 | 45.33 |

| 6.80 | 73.48 | 46.44 |

| 6.90 | 75.72 | 47.51 |

| 7.00 | 78.00 | 48.57 |

| 7.10 | 80.25 | 49.61 |

| 7.20 | 82.39 | 50.69 |

| 7.30 | 84.53 | 51.78 |

| 7.40 | 86.66 | 52.88 |

| 7.50 | 88.85 | 53.98 |

| 7.60 | 91.04 | 55.09 |

| 7.70 | 93.20 | 56.20 |

| 7.80 | 95.43 | 57.31 |

| 7.90 | 97.72 | 58.45 |

| 8.00 | 100.0 | 59.60 |

| 8.10 | 102.3 | 60.74 |

| 8.20 | 104.6 | 61.89 |

| 8.30 | 106.9 | 63.05 |

| 8.40 | 109.2 | 64.18 |

| 8.50 | 111.5 | 65.32 |

| 8.60 | 113.9 | 66.48 |

| 8.70 | 116.2 | 67.64 |

| 8.80 | 118.5 | 68.79 |

| 8.90 | 120.9 | 69.94 |

| 9.00 | 123.3 | 71.10 |

| 9.10 | 125.7 | 72.27 |

| 9.20 | 128.0 | 73.42 |

| 9.30 | 130.4 | 74.57 |

| 9.40 | 132.8 | 75.73 |

| 9.50 | 135.3 | 76.91 |

| 9.60 | 137.7 | 78.08 |

| 9.70 | 140.1 | 79.27 |

| 9.80 | 142.7 | 80.46 |

| 9.90 | 145.2 | 81.67 |

| 10.0 | 147.7 | 82.87 |

| 10.1 | 150.3 | 84.08 |

| 10.2 | 152.9 | 85.30 |

| 10.3 | 155.4 | 86.51 |

| 10.4 | 158.0 | 87.72 |

| 10.5 | 160.6 | 88.95 |

| 10.6 | 163.2 | 90.19 |

| 10.7 | 165.8 | 91.40 |

| 10.8 | 168.5 | 92.65 |

| 10.9 | 171.2 | 93.92 |

| 11.0 | 173.9 | 95.19 |

| 11.1 | 176.6 | 96.45 |

| 11.2 | 179.4 | 97.71 |

| 11.3 | 182.1 | 98.97 |

| 11.4 | 184.9 | 100.2 |

| 11.5 | 187.6 | 101.5 |

| 11.6 | 190.4 | 102.8 |

| 11.7 | 193.3 | 104.1 |

| 11.8 | 196.2 | 105.4 |

| 11.9 | 199.0 | 106.7 |

| 12.0 | 201.9 | 108.0 |

| 12.1 | 204.8 | 109.4 |

| 12.2 | 207.8 | 110.7 |

| 12.3 | 210.7 | 112.0 |

| 12.4 | 213.6 | 113.3 |

| 12.5 | 216.6 | 114.7 |

| 12.6 | 219.6 | 116.0 |

| 12.7 | 222.6 | 117.4 |

| 12.8 | 225.7 | 118.7 |

| 12.9 | 228.8 | 120.1 |

| 13.0 | 231.9 | 121.5 |

| 13.1 | 265.0 | 122.9 |

| 13.2 | 238.1 | 124.2 |

| 13.3 | 241.2 | 125.6 |

| 13.4 | 244.3 | 127.0 |

| 13.5 | 247.4 | 128.4 |

| 13.6 | 250.6 | 129.8 |

| 13.7 | 253.8 | 131.8 |

| 13.8 | 257.0 | 132.6 |

| 13.9 | 260.1 | 134.0 |

| 14.0 | 263.3 | 135.4 |

| 14.1 | 266.6 | 136.8 |

| 14.2 | 269.8 | 138.2 |

| 14.3 | 273.0 | 139.6 |

| 14.4 | 276.3 | 141.0 |

| 14.5 | 279.6 | 142.4 |

| 14.6 | 283.0 | 143.9 |

| 14.7 | 286.4 | 145.3 |

| 14.8 | 289.7 | 146.8 |

| 14.9 | 293.0 | 148.2 |

| 15.0 | 296.5 | 149.7 |

| 15.1 | 300.0 | 151.2 |

| 15.2 | 303.4 | 152.6 |

| 15.3 | 306.9 | 154.1 |

| 15.4 | 310.3 | 156.6 |

| 15.5 | 313.9 | 157.0 |

| 15.6 | 317.5 | 158.6 |

| 15.7 | 321.1 | 160.1 |

| 15.8 | 324.6 | 161.6 |

| 15.9 | 328.3 | 163.1 |

| 16.0 | 331.9 | 164.6 |

| 16.1 | 335.5 | 166.1 |

| 16.2 | 339.2 | 167.7 |

| 16.3 | 342.9 | 169.2 |

| 16.4 | 346.6 | 170.7 |

| 16.5 | 350.3 | 172.3 |

| 16.6 | 354.1 | 173.8 |

| 16.7 | 358.0 | 175.4 |

| 16.8 | 361.7 | 177.0 |

| 16.9 | 365.6 | 178.6 |

| 17.0 | 369.4 | 180.2 |

| 17.1 | 373.3 | 181.7 |

| 17.2 | 377.1 | 183.3 |

| 17.3 | 381.0 | 184.9 |

| 17.4 | 384.9 | 186.5 |

| 17.5 | 388.9 | 188.1 |

| 17.6 | 392.7 | 189.7 |

| 17.7 | 396.7 | 191.3 |

| 17.8 | 400.7 | 192.9 |

| 17.9 | 404.6 | 194.6 |

| 18.0 | 408.6 | 196.2 |

| 18.1 | 412.6 | 197.8 |

| 18.2 | 416.7 | 199.4 |

| 18.3 | 420.7 | 201.0 |

| 18.4 | 424.9 | 202.6 |

| 18.5 | 429.0 | 204.3 |

| 18.6 | 433.2 | 205.9 |

| 18.7 | 437.3 | 207.6 |

| 18.8 | 441.5 | 209.3 |

| 18.9 | 445.7 | 211.0 |

| 19.0 | 449.9 | 212.7 |

| 19.1 | 454.2 | 214.4 |

| 19.2 | 458.4 | 216.1 |

| 19.3 | 462.7 | 217.7 |

| 19.4 | 467.0 | 219.4 |

| 19.5 | 471.3 | 221.1 |

| 19.6 | 475.7 | 222.8 |

| 19.7 | 479.7 | 224.5 |

| 19.8 | 483.9 | 226.2 |

| 19.9 | 488.6 | 227.7 |

| 20.0 | 493.2 | 229.5 |

| 20.2 | 501.5 | 233.0 |

| 20.4 | 510.8 | 236.4 |

| 20.6 | 519.9 | 240.1 |

| 20.8 | 528.8 | 243.5 |

| 21.0 | 538.4 | 247.1 |

| 21.2 | 547.5 | 250.7 |

| 21.4 | 556.7 | 254.2 |

| 21.6 | 566.4 | 257.8 |

| 21.8 | 575.6 | 261.5 |

| 22.0 | 585.2 | 264.9 |

| 22.2 | 595.0 | 268.6 |

| 22.4 | 604.3 | 272.3 |

| 22.6 | 614.2 | 275.8 |

| 22.8 | 624.1 | 279.6 |

| 23.0 | 633.6 | 283.3 |

| 23.2 | 634.4 | 286.3 |

| 23.4 | 653.8 | 290.5 |

| 23.6 | 663.3 | 294.4 |

| 23.8 | 673.7 | 297.9 |

| 24.0 | 683.9 | 301.8 |

| 24.2 | 694.5 | 305.6 |

| 24.4 | 704.2 | 309.4 |

| 24.6 | 714.9 | 313.0 |

| 24.8 | 725.7 | 317.0 |

| 25.0 | 736.5 | 320.9 |

| 25.2 | 747.2 | 324.9 |

| 25.4 | 758.2 | 328.8 |

| 25.6 | 769.3 | 332.7 |

| 25.8 | 779.7 | 336.7 |

| 26.0 | 790.4 | 340.5 |

| 26.2 | 801.6 | 344.4 |

| 26.4 | 812.8 | 348.4 |

| 26.6 | 824.1 | 352.3 |

| 26.8 | 835.5 | 356.4 |

| 27.0 | 847.0 | 360.5 |

| 27.2 | 857.5 | 364.6 |

| 27.4 | 869.0 | 368.3 |

| 27.6 | 880.6 | 372.3 |

| 27.8 | 892.3 | 376.4 |

| 28.0 | 904.1 | 380.6 |

| 28.2 | 915.8 | 384.6 |

| 28.4 | 927.6 | 388.8 |

| 28.6 | 938.6 | 393.0 |

| 28.8 | 951.2 | 396.6 |

| 29.0 | 963.4 | 401.1 |

| 29.2 | 975.4 | 405.3 |

| 29.4 | 987.1 | 409.5 |

| 29.6 | 998.9 | 413.5 |

| 29.8 | 1011 | 417.6 |

| 30.0 | 1023 | 421.7 |

| 30.5 | 1055 | 432.4 |

| 31.0 | 1086 | 443.2 |

| 31.5 | 1119 | 454.0 |

| 32.0 | 1151 | 464.9 |

| 32.5 | 1184 | 475.9 |

| 33.0 | 1217 | 478.0 |

| 33.5 | 1251 | 498.1 |

| 34.0 | 1286 | 509.6 |

| 34.5 | 1321 | 521.1 |

| 35.0 | 1356 | 532.5 |

| 35.5 | 1391 | 544.0 |

| 36.0 | 1427 | 555.6 |

| 36.5 | 1464 | 567.1 |

| 37.0 | 1501 | 579.3 |

| 37.5 | 1538 | 591.3 |

| 38.0 | 1575 | 603.1 |

| 38.5 | 1613 | 615.0 |

| 39.0 | 1651 | 627.1 |

| 39.5 | 1691 | 639.2 |

| 40.0 | 1730 | 651.8 |

| 40.5 | 1770 | 664.2 |

| 41.0 | 1810 | 676.6 |

| 41.5 | 1851 | 689.1 |

| 42.0 | 1892 | 701.9 |

| 42.5 | 1935 | 714.9 |

| 43.0 | 1978 | 728.2 |

| 43.5 | 2021 | 741.3 |

| 44.0 | 2064 | 754.4 |

| 44.5 | 2108 | 767.6 |

| 45.0 | 2152 | 780.9 |

| 45.5 | 2197 | 794.5 |

| 46.0 | 2243 | 808.2 |

| 46.5 | 2288 | 821.9 |

| 47.0 | 2333 | 835.5 |

| 47.5 | 2380 | 849.2 |

| 48.0 | 2426 | 863.0 |

| 48.5 | 2473 | 876.9 |

| 49.0 | 2521 | 890.9 |

| 49.5 | 2570 | 905.3 |

| 50.0 | 2618 | 919.6 |

| 50.5 | 2667 | 933.6 |

| 51.0 | 2717 | 948.2 |

| 51.5 | 2767 | 962.9 |

| 52.0 | 2817 | 977.5 |

| 52.5 | 2867 | 992.1 |

| 53.0 | 2918 | 1007 |

| 53.5 | 2969 | 1021 |

| 54.0 | 3020 | 1036 |

| 54.5 | 3073 | 1051 |

| 55.0 | 3126 | 1066 |

| 55.5 | 3180 | 1082 |

| 56.0 | 3233 | 1097 |

| 56.5 | 3286 | 1112 |

| 57.0 | 3340 | 1127 |

| 57.5 | 3396 | 1143 |

| 58.0 | 3452 | 1159 |

| 58.5 | 3507 | 1175 |

| 59.0 | 3563 | 1190 |

| 59.5 | 3619 | 1206 |

| 60.0 | 3676 | 1222 |

| 60.5 | 3734 | 1238 |

| 61.0 | 3792 | 1254 |

| 61.5 | 3850 | 1270 |

| 62.0 | 3908 | 1286 |

| 62.5 | 3966 | 1303 |

| 63.0 | 4026 | 1319 |

| 63.5 | 4087 | 1336 |

| 64.0 | 4147 | 1352 |

| 64.5 | 4207 | 1396 |

| 65.0 | 4268 | 1386 |

| 65.5 | 4329 | 1402 |

| 66.0 | 4392 | 1419 |

| 66.5 | 4455 | 1436 |

| 67.0 | 4517 | 1454 |

| 67.5 | 4580 | 1471 |

| 68.0 | 4645 | 1488 |

| 68.5 | 4709 | 1506 |

| 69.0 | 4773 | 1523 |

| 69.5 | 4839 | 1541 |

| 70.0 | 4905 | 1558 |

To determine the viscosity index, we can use the following formula:

![]()

The symbols that are used in the above formula are the following:

- VI: viscosity index

- U: the kinematic viscosity of the wanted oil sample at 40°C (mm2/s)

- L: the viscosity index of that base oil at 40°C (mm2/s), which has a viscosity index of 0, and its viscosity at 100°C is the same as the viscosity of the wanted oil

- H: the viscosity index of that base oil at 40°C (mm2/s), which has a viscosity index of 100, and its viscosity at 100°C is the same as the viscosity of the wanted oil

The following graph shows the determining of viscosity index: